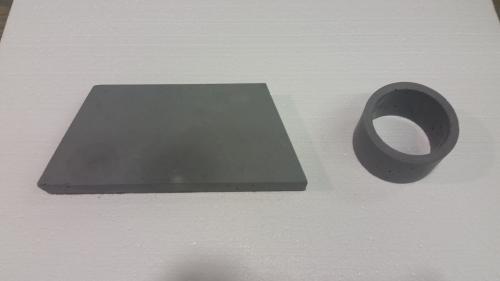

Ceramic Fiber Boards

Cerablanket®, Cerachem® Blanket & Cerachrome® Blanket

Ceramic fiber boards are viable options for insulation. These boards are made using alumina-silica fibers and binders through a wet forming process. Different ceramic fiber boards can withstand different temperatures—meaning they have different temperature ratings. They also differ in densities, thickness, width, length, and shapes.

This durable material makes for excellent insulation and other high-temperature applications because of their heavy-duty nature. Features of ceramic fiber boards include:

- Lightweight

- Easy install

- Very low heat loss

- No asbestos

- Tough and durable

- Low thermal conductivity

- Low thermal density

- Resists high velocities

- High-temperature stability

- Resistance against chemical attack

- Resistance against thermal shock

- Resists oxidation

- High heat storage

There are several different applications for ceramic fiber boards. They may be used for industrial use or in a residential home, but most commonly in industrial insulation or high temperatures. Applications for ceramic fiber boards include:

- Insulation

- Industrial heat process equipment

- Hot face lining

- High temp gaskets

- High temp seals

- Molten metal covers

- Chimney linings

- Linings in furnaces

- Refractory lining

- Heat shields

- Thermal barriers

- Fire protection

- Combustion chambers

- Heat shields

- Boiler ducts

- Boiler stacks

In some cases, ceramic fiber boards may be exposures to water or oil. When this happens, the boards will be fully restored, virtually unaffected after dried.

WHY CHOOSE US?

At Mountain View Power, we provide ceramic fiber boards for all of your insulation needs. Whether you need to resist high velocities, line a furnace, insulation, or something else—ceramic fiber boards can get the job done. High-temperature application needs can all be met, but these boards from Mountain View Power. Contact us today to get some of this durable material.