Acid & Corrosion

(Click on Logo above for additional info)

For more than 115 years, Atlas Minerals & Chemicals has been developing and manufacturing the world’s most reliable CCM (Corrosion-Resistant Construction Materials), Epoxybond® repair products, industrial compounds, and oxidized asphalt. Atlas also specializes in custom plastic fabrication.

Headquartered in Pennsylvania’s Lehigh Valley, Atlas provides customers around the world with end use solutions across an endless array of specialized industries. Our long history includes countless industry firsts, and our future holds day after day of new innovations designed to make your job easier.

Corrosion-Resistant Construction Materials

• Setting Beds, Grouts, & Mortars

• Linings & Membranes

• Primers

• Coatings

• Polymer Floors

• Expansion Joints

• Polymer Concrete

• Surface Preparation

Thermoplastic Linings

Anchor-Lok Lining System

• Used in conjunction with concrete construction • Mechanically anchored into concrete substrate • Leak-free primary and second containment and corrosion protection • Leak detection systems available • Expansion joints not required • Available in five thermoplastic resins

• Chemical resistance • Thermal resistance • Impact and abrasion resistant • Bridges cracks in concrete • Easy installation

• Prefabricated construction available for new construction or retrofit

• Trenches, Sumps, Tanks, Drains

• Any configuration size or shape

• Built-in grating seat

• Conform to ASTM and DIN standards

• Welded by Certified Applicators

• Standard sheet thicknesses are 1/8″ (3 mm.) and 3/16″ (5 mm.)

Installation Guidelines

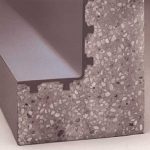

Chemical Resistant Brick: Red Shale & Fire Clay Brick

Belden shale and fire clay chemical resistant brick offer engineers a wide range of utility in environments that involve aggressive corrosive conditions and elevated temperatures.

These brick are currently in use in such industries as chemicals, steel, and metalworking, pharmaceuticals, pulp and paper, food and beverage, public utilities, aircraft, automotive and electronics. Typical applications in these industries are represented by process vessels, plating tanks, storage tanks, reaction vessels, fume ducts, scrubbers, bleach towers, waste treatment pits, rinse lines, and pickling tanks.

Chemical resistant masonry construction is designed to protect containment tanks and vessels made of steel, concrete, ordinary masonry, fiber-reinforced polyesters and the like. Chemical resistant brick provides thermal, mechanical, and chemical protection for these kinds of structures.

Belden chemical resistant brick is a particularly versatile construction material for sulfuric acid plants when installed as linings for carbon steel shells. These linings can be used regardless of the size of the vessels or equipment when prescribed construction techniques are followed. They can lower the temperature of the surface of the shell and eliminate erosion of the protective sulfate film. No other system of corrosion resistance can provide the same level of cost effective protection in wet areas where acid concentrations vary from 2% to 98% and at high temperatures, as the three component system using chemical resistant brick and mortar with a membrane backing.

WHY CHOOSE US?

We have in stock a furan setting bed/mortahouse your maintenance materials in our Salt Lake City Utah location, available 24/7. We work with the oldest established company in the industry so there isn’t a problem we can’t solve